Vacuum technology, often overlooked in everyday life, plays an important role in a variety of industries, influencing forms that extend from manufacturing and healthcare to space exploration. This article explores the far-reaching applications of vacuum technology, shedding light on its important role in shaping technological progress and innovation.

Introduction to Vacuum Technology

Delving into the world of vacuum technology is essentially the art of playing with weight, orchestrating a dance where pressure levels take center stage, creating a vacuum – where weight conveniently descends under a familiar atmospheric ceiling.

In this complex performance, the magic lies in creating controllable domains where the discussion is less thick, which opens the door for various industrial maneuvers and logical abuses to a domain of unimaginable consequences. It is like refining a symphony of air to create an orchestra of controlled situations that reverberates through a tapestry of mechanical forms and scientific experiments.

Applications of Vacuum Technology in Space Exploration

Vacuum Chambers for Spacecraft Testing

The magic of spaceship testing scenes, where vacuum technology is the focus. In the space theater, vacuum chambers, capable of energetic vacuum technology, become an absolute highlight. These cameras are not simple props; They are unrecognized space exploration modelers who lead the orchestra of tests on spacecraft. satellite component

For now, how about focusing on the feature act: vacuum technology? It coordinates the control of the tension level that creates the air voids in these chambers. Here, engineers take on the part of space guides, who quickly scan the presentation and variety of room-related devices in a climate that mirrors the room’s vacuum condition.

Thus, when you hear “vacuum technology” in connection with spacecraft testing, imagine a maestro behind the stage creating controlled conditions that push the limits of technology. It is a quiet force that propels us into cosmic obscurity, assuring us that each piece of machinery is not simply a cosmic compliment, but a sparkling star in a heavenly expressive dance.

Simulation of Space Conditions

Step into the world of vacuum technology, a space-enhancing agent that allows researchers and designers to reflect on the brutal real-world factors of space. In this mechanical dance, vacuum technology creates simulations with precision, facing outrageous temperatures and lack of air. These simulations become the pot that appreciates the permanence of materials and frameworks for divine excursions.

As a cosmic maestro, Vacuum technology organizes these simulations that undergo simple replication. It is an essential demonstration, an extension between the natural domains and the cosmic void, guaranteeing that each material and situation can withstand the suffering of space. It’s not just about testing; It is a cosmic practice that strengthens the components to shine like stars when the final curtain rises on the cosmic stage.

Use of Vacuum Technology in Electronics Manufacturing

Thin Film Deposition

The versatile world of electronics manufacturing, where vacuum technology is beginning to lead in thin-film display. Vacuum chambers are unremarkable but truly remarkable individuals who organize the fragile cycle that is important in the creation of semiconductors.

In this ballet of technology, a minor film statement emerges as a prima ballerina. The method gently deposits a thin layer of material onto a substrate within the vacuum confines of these chambers. Vacuum Technology, directed by the choreographer, guarantees that the exhibition will develop without any trace of resistance in the air. Result? Precise and uniform coatings form the basis for the consistent production of complex electronic components. It’s not just interaction; It’s a dance of precision where vacuum technology conjures up the means that rejuvenate semiconductor dreams.

Sputtering

Enter the domain of electronics manufacturing, where the decisive demonstration of failure takes on such a grand appearance. This complex cycle involves a rich dance of particles as they nimbly leave the objective material and settle on the substrate, forming a thin film framework.

In this cosmic dance, the vacuum climate becomes a silent sentinel, killing pesky gas molecules that could disrupt the fragile application process. Vacuum technology does the job of cosmic director, arranging the atmosphere without any trace of resistance, where each particle precisely controls its place. The result is not just a delicate film; It’s a great piece of statement art, demonstrating the symbiotic relationship between technology and the flawless embrace of vacuum.

Etching

In semiconductor manufacturing, vacuum technology plays an important role in etching processes. This involves gently removing unwanted materials from semiconductor wafers to carve out complex circuit designs. Acting as quiet accomplices, vacuum chambers guarantee a pristine climate to work with this precision, helping to eliminate reactive side effects and contaminants. The result is an improvement in the accuracy of engraving processes, demonstrating the consistent cooperation between technology and a controlled vacuum atmosphere.

Medical Applications of Vacuum Technology

Freeze-Drying Pharmaceuticals

In the pharmaceutical field, vacuum technology is becoming a dominant focal point in freeze-drying processes that are vital for the preservation and stabilization of pharmaceuticals and biological materials. This strategy involves the substantial removal of moisture under a vacuum, organized by vacuum technology. Think of it as a gateway to pharmaceutical integrity, ensuring that medicines and biologics can be abandoned for long periods without degradation.

Vacuum-Assisted Wound Healing

Enter the realm of medical innovation where vacuum technology plays a leading role in the specialty of torsional healing through vacuum-assisted closure (VAC) therapy. This medical procedure uses specific vacuum gadgets to apply a negative charge to the injury site, which acts as a therapeutic assistant in the healing process. Think of it as a gentle force that guides the body’s normal healing process, removing excess fluids and promoting tissue repair for a faster healing encounter.

In the narrative of wound administration, vacuum technology becomes a healing friend, optimizing the climate for tissue repair. The negative tension applied by specific vacuum gadgets acts like a strong hand, speeding up the healing process by effectively eliminating excess fluids. It is not just a medical procedure; It is a declaration of cooperation between technology and medical care, where vacuum technology takes a decisive role in promoting faster and stronger healing of injuries.

Vacuum Technology in Analytical Instruments

Mass Spectrometers

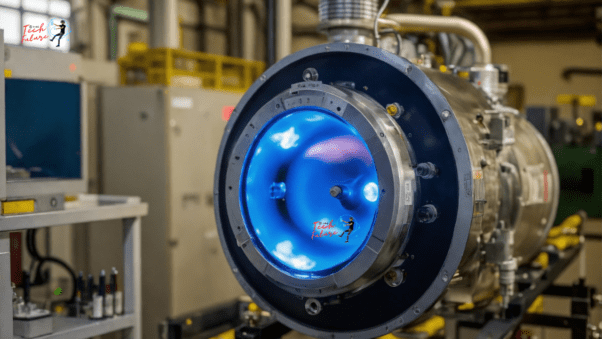

A world of scientific precision with mass spectrometers where vacuum technology begins to lead. These instruments leverage vacuum technology to probe the organization of matter by measuring the ionization of molecules and their mass-to-charge ratios. Think of it as a molecular investigator at work, unraveling the intricacies of molecular structures.

In this scientific ballet, a vacuum chamber turns to examine a pristine stage. The role of vacuum technology is vital – it removes air molecules from the chamber, providing a zone without interfering with the ionization process. This meticulous orchestration provides precise and robust logical results, presenting an indispensable organization between technology and the mission for scientific understanding. It’s not just about analyzing molecules; It is about the precision etched by a controlled vacuum environment, demonstrating the complex dance of mass spectrometers in the field of scientific research.

Electron Microscopes

Electron microscopes are in the spotlight, which use vacuum technology to operate under high vacuum conditions. This substantial vacuum environment is filled as a stage for imaging examples of nanoscale targets. By eliminating air molecules, vacuum technology prevents the scattering and trapping of electrons, paving the way for extraordinary clarity and enhancement of individual images. It’s a mechanical ballet where the lack of interference allows electron microscopes to reveal the secret intricacies of the tests, illustrating the indispensable role of vacuum technology in nanoscale exploration.

Spectrophotometers

Spectrophotometers are becoming the dominant focal point for measuring the absorption, transmission, and emission of light by substances in a variety of research applications. The key to their accuracy is the integration of vacuum technology, which is crucially used to eliminate the interference of air molecules.

This vacuum environment is filled as a protective shield, guaranteeing that spectrophotometers deliver accurate and reliable measurements. It is a mechanical favorable interaction, where the lack of air interference guarantees the constancy of logical results, which emphasizes the indispensable role of vacuum technology in the field of extraterrestrial exploration and scientific investigation.

Vacuum Packaging in the Food Industry

In the dynamic food industry scene, Vacuum Technology emerges as a protection partner through vacuum packaging. This generally accepted technique plays a crucial part in extending the shelf life of short-lived products. As the air is carefully expelled from the package, the vacuum technology makes it look great, preventing oxidation and microbial development.

The result is protection against aging, maintaining the quality and freshness of food products, and ensuring they reach consumers with a long shelf life. It is a culinary dance where vacuum technology works as a gatekeeper, enhancing the shelf life and maintaining the pleasant appeal of various food products.

Metallurgy and Material Processing

Vacuum Casting

Vacuum casting is in the spotlight as a process that combats vacuum technology to create excellent metal components with minimal defects. This metallurgical ballet is opened by evacuating the air from the casting chamber, allowing the liquid metal to fill the mold.

The result is a meticulous dance of precision and homogeneity, producing a metal casting that boasts minimal porosity and imperfections. Vacuum technology acts as a hidden choreographer that orchestrates the environment where each mold is flawlessly filled, ensuring the production of precise and first-class metal components.

Vacuum Heat Treatment

Vacuum heat treatment leads the pack, which uses vacuum technology to raise metal components to apparent mechanical capabilities and surface finishes. Within the confines of a vacuum heater, without any trace of oxygen or other gases, this meticulous process takes place, preventing oxidation and decarburization.

The result is a controlled orchestration of heat treatment, where metal components are painstakingly heated to achieve desired properties with minimal bending. Vacuum technology works like a quiet modeler, creating an environment where precise control rules ensure that the result reflects updated mechanical characteristics as well as a flawless surface finish.

Vacuum Technology in the Chemical Industry

Vacuum Distillation

Vacuum distillation becomes an absolute focus as the process, which uses vacuum technology to distill high boiling points, is intensified under reduced pressure. The magic here lies in lowering the boiling point of the components, organized by vacuum technology.

This essential control provides the separation of heat-sensitive and volatile substances with improved productivity and purity. It is a chemical ballet where vacuum technology fills like a virtuoso director, harmonizing the distillation conditions with precision, ensuring that the final product is an orchestra of well-isolated and purified substances.

Separation and Purification Processes

In the complex landscape of chemical synthesis and purification, vacuum technology is emerging as a flexible device used in separation processes such as filtration, evaporation, and crystallization. These processes develop in vacuum conditions, where the lack of air becomes the impetus for improved knowledge.

Vacuum technology works with the thorough evacuation of solvents and contamination, driving a cleaning orchestra that delivers refined and filtered chemical products. Think of him as a quiet craftsman refining a chemical magnum opus, ensuring the result is not just a thing, but a carefully refined creation shaped by the precision and productivity of vacuum-assisted partitioning processes.

Aerospace Applications of Vacuum Technology

Testing Aerospace Components

Dependence on vacuum technology is evident, especially in the testing of shuttle and satellite systems. Aerospace engineers approach vacuum chambers as important tools that simulate vacuum conditions in the harsh climate of space.

In these chambers, engineers carefully evaluate the performance and reliability of aerospace components by exposing them to extreme environmental conditions. It’s not just testing; It’s a huge practice where vacuum technology becomes a course for testing the strength of aerospace components, ensuring they can explore the challenging realms of space with robust performance and reliability.

Lightweight Material Production

Vacuum technology is becoming a dominant focus in the production of lightweight materials such as composites and foams. Aerospace applications require materials that are both light and strong, and vacuum technology plays an important role in achieving this balance.

Air bubbles and voids are carefully eliminated through vacuum-assisted manufacturing processes, ensuring that the resulting materials are lightweight and durable. It is a mechanical dance where vacuum technology plays the role of maestro, orchestrating the fabrication of aerospace materials that combine weightlessness and durability, preparing for the construction of advanced and efficient aerospace structures.

Research and Development Utilizing Vacuum Chambers

In the field of scientific research, vacuum chambers stand as indispensable tools in research and development laboratories. These chambers become controlled environments where scientists and engineers conduct experiments, pushing the boundaries of knowledge in disciplines such as materials science, physics, and chemistry.

Vacuum technology, acting as a silent facilitator, ensures that these controlled conditions are free from interference, allowing for accurate and reliable scientific investigations. It is a multifaceted symphony where vacuum chambers become the scene of a wide range of research, contributing to innovative achievements and discoveries in the fields of science and technology.

Vacuum Technology in the Energy Industry

Vacuum Circuit Breakers

Vacuum circuit breakers are formed as protectors used to interrupt and isolate fault currents. These essential devices rely on the mastery of vacuum technology to quickly extinguish electrical arcs, ensuring not only operational reliability but also the safety of power transmission networks.

Think of these circuit breakers as vigilant sentinels, using the precision of vacuum technology to quickly extinguish electrical arcs, thereby preventing potential disruptions and hazards in the complex dance of power distribution. It is a technological ballet where vacuum technology takes center stage, providing a critical mechanism for maintaining the stability and safety of electrical systems.

Vacuum Insulation

The idea of vacuum protection is becoming a major focus to limit energy disasters and improve the efficiency of electrical devices. Devices that use vacuum protection, such as vacuum breakers and bushings, offer better protection properties during analysis than traditional gas-insulated systems.

This technological leap improves efficiency and also provides for more conservative and reliable electrical installations. Think of vacuum protection as a quiet designer that creates solid and efficient boundaries against energy disasters in the mind-boggling landscape of high-voltage electrical applications, preparing for advanced and robust electrical systems.

Conclusion

In the intricate trap of technological advancement, vacuum technology arises as an overlooked yet truly great individual, weaving its impact across different enterprises. From the vast reaches of space to the minute universe of gadgets, its applications are as expansive as they are essential. As we navigate the intricacies of current life, the quiet efficiency of vacuum technology plays a crucial role in advancing our understanding and capabilities.

Frequently Asked Questions (FAQs)

How does vacuum technology contribute to environmental sustainability?

Vacuum technology, when employed in processes like freeze-drying and efficient material processing, can contribute to environmental sustainability by reducing energy consumption and waste.

Are there any emerging trends in vacuum technology?

Yes, ongoing research focuses on developing more energy-efficient vacuum technologies and exploring new applications in emerging fields like quantum computing and nanotechnology.

Can vacuum technology be harnessed for clean energy production?

Research is underway to explore the potential of vacuum technology in clean energy production, such as harnessing vacuum fluctuations for power generation.

Is there a limit to how “deep” a vacuum can be created?

While extremely high vacuums are achievable in laboratory settings, there is a theoretical limit called the ultimate vacuum, beyond which it is impossible to remove all particles.

How does vacuum technology impact the cost of manufacturing in various industries?

Vacuum technology can contribute to cost savings in manufacturing by enhancing precision, reducing material waste, and improving the efficiency of various processes.